Cellular oxidation, or oxidative stress, is the ultimate consequence of any stress experienced by an organism. In other words, it’s an aggression to the cell thus causing damage and a notable disturbance of its functioning. Exhaustion and physiological disorders are the objective criteria to assess oxidative stress. “For tomato growers, this means that no matter how highly technological or automated their greenhouse is. They would ultimately not be able to achieve the expected yield and quality,” says Roman Guy Technical manager from Biodevas, a company specializing in natural solutions to address the most pressing challenges in agriculture. “In other words, when oxidative stress is occurring, a grower wouldn’t be able to fully exploit the tech in the greenhouse, the genetic potential of the variety in question, and so on. This is due to the exhaustion of the plants subjected to a high level of performance, their increased fragility, and their premature aging.”

It is for that reason that the company has created the FRUCTA biostimulant. “Our product is systemic, which allows complete control of the oxidative stress,” Roman continues. “Treated plants are more resilient to common stressors such as lack of light, temperature variations, and pathogens, thus allowing the crop to express its full genetic potential.”

Dealing with oxidative stress

The company has conducted some trials to test the yield and quality improvement. “Over the last 5 years, we have carried out a large series of trials directly with growers to gather data on the most common varieties like Xavierus, Clodano, and Trovenzo. At the same time, we also did it for more niche varieties such as Romanella, Briozo, and Bartelly. All the results have pointed in the same direction, with a 3-10% yield increase.”

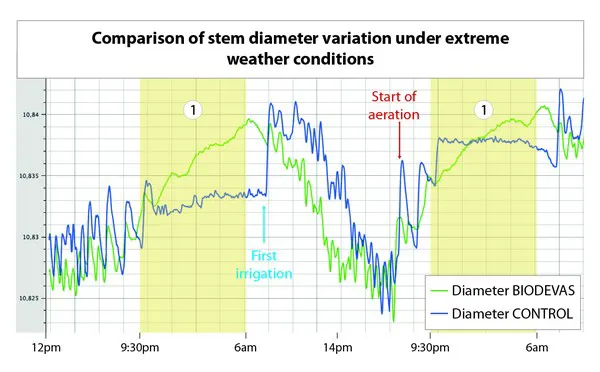

To better understand the inner dynamics at play in this increase, the company did another similar trial with the addition of 2GROW probes. “The precision of the measurements allowed us to demonstrate in real time a radically different behavior in production conditions,” Roman points out. “This difference was observed in the night recovery, the sensitivity to irrigation, and the sensitivity to hygrometry in the greenhouse. On top of this, we did another trial at the Vertify Station in the Netherlands. This trial was conducted with the Bartelly cherry tomatoes, and resulted in a 9% yield improvement.”

ROI

Considering the yield increase though, what is the ROI? “The program we suggest is a weekly injection of 5 L/ha of our product from planting until the end of the harvest,” Roman says. “At the same time, the ROI of our product varies depending on the variety and the time of the year. We note that the economic gain of a treated crop is at least 5 times the cost of the treatment for tomato crops. It should also be noted that the product can be applied automatically using a dosing pump or a venturi system. When applied in this way, it’s less labor but it mainly does not affect the development of biological control as there’s no foliar pulverization. On top of that, our product has an Iso22000 certification, which guarantees it’s harmless, with regards to both the repeatability of our manufacturing process and the total absence of residues.”

Although the current economic uncertainties might have repercussions on protected cropping, there are still a lot of opportunities to seize. “In 2023, we will start experimenting with low inputs technical itineraries: lowering heating settings, limiting CO2 emissions, reducing lighting, etc. We constantly talk to growers and listen to their feedback and input. That is what guides our projects. Each year, we devote 10% of our turnover to R&D, this is the DNA of our company.”

For more information:

Biodevas

Thierry Roger

+33 (0)6 02 09 08 95

troger@biodevas.fr

biodevas.com